Detailed explanation of packaging box production materials

As the name suggests, the packaging box is a box used to package products. Beautiful packaging boxes are always loved by people. However, what material are these exquisite packaging boxes made of?

Packaging boxes can be divided into: cartons, iron boxes, wooden boxes, cloth boxes, leather boxes, acrylic boxes, corrugated packaging boxes, PVC boxes, etc. The commonly used materials for packaging cartons can be divided into two categories: tissue paper, pit paper.

Today, let's learn about the tissue paper and pit paper materials commonly used in packaging boxes!

01, tissue paper

Commonly used cardboard in cardboard are: coated paper, gray paper, special paper

Coated paper

Coated paper includes gray copper, white copper, single copper, gorgeous cards, gold cards, platinum cards, silver cards, laser cards, etc.

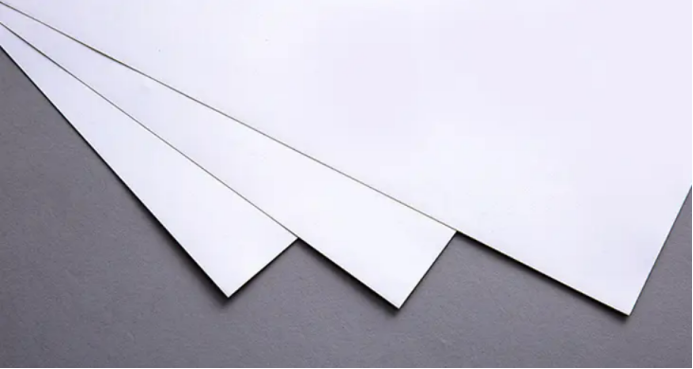

"Whiteboard with white background" is called white copper and single copper, which belong to the same kind of cardboard.

"Double copper": There are coating surfaces on both sides, and both sides can be printed.

The common point between white copper and double copper is that both sides are white. The difference is that white copper can be printed on the front side, while the reverse side cannot be printed, while both sides of double copper can be printed.

General white cardboard is also called "single powder card" paper, and also called "single copper paper".

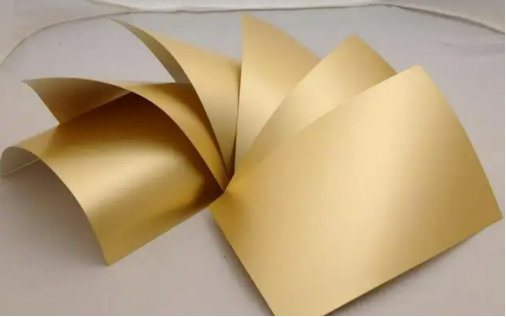

Gold cardboard

Silver cardboard

Laser card

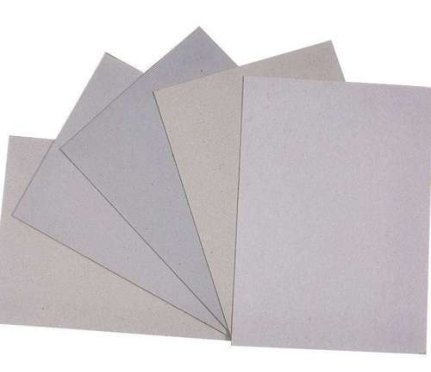

Greyboard paper is divided into gray-based gray board and gray-based whiteboard. Grey-based gray board: not used in packaging box printing manufacturers;

Greyboard

Whiteboard with gray background: It is the so-called "pink paper, pink board paper", that is, the front is white and can be printed, and the reverse is gray and cannot be printed. It is also called "whiteboard", "gray cardboard", "single-sided white", the cost of this carton is relatively low.

Generally, white card is also called "white board" paper, also known as double powder paper. White card paper is better, with sufficient texture and hardness, and the price is expensive.

Determine the material of the packaging box according to the shape and size of the product: commonly used materials are: 280g powder gray paper, 300g powder gray paper, 350g powder gray paper, 250g powder gray mounted E pit, 250g double powder paper mounted E pit, etc

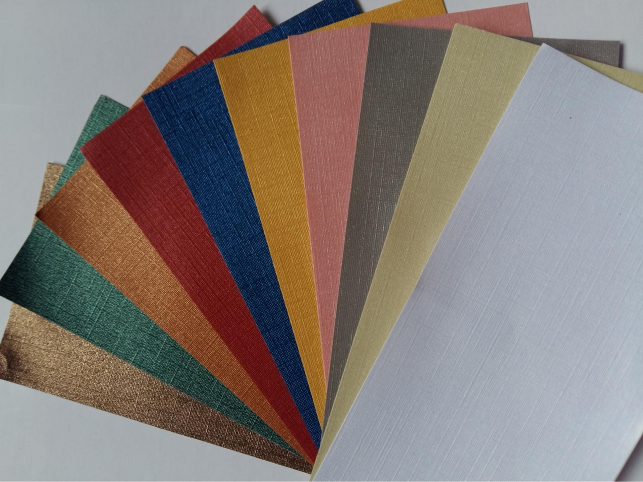

Special paper: Paper with special purposes and relatively small output.

Specialty paper

There are many types of special paper, which is a general term for various special purpose paper or art paper. These papers are specially treated to improve the texture of packaging.

The surface embossing and embossing of special paper cannot be printed, only surface hot stamping, star mining, gold paper, etc. can be printed in 4 colors.

Common types of special paper: leather-filled paper series, velvet series, gift packaging series, two-color pearl series, pearl paper series, two-color glossy series, glossy series, wrapping paper series, dumb wood black card series, raw pulp color card series, Lishi sealing paper series.

The commonly used surface treatment processes after facial paper printing are: glue, UV, hot stamping, and embossing.

02. Pit paper

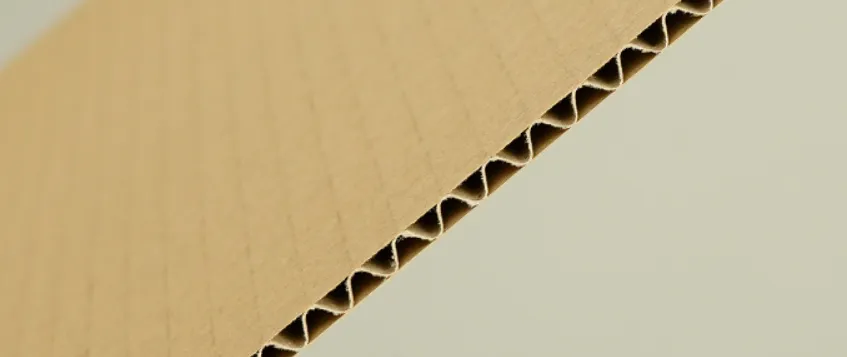

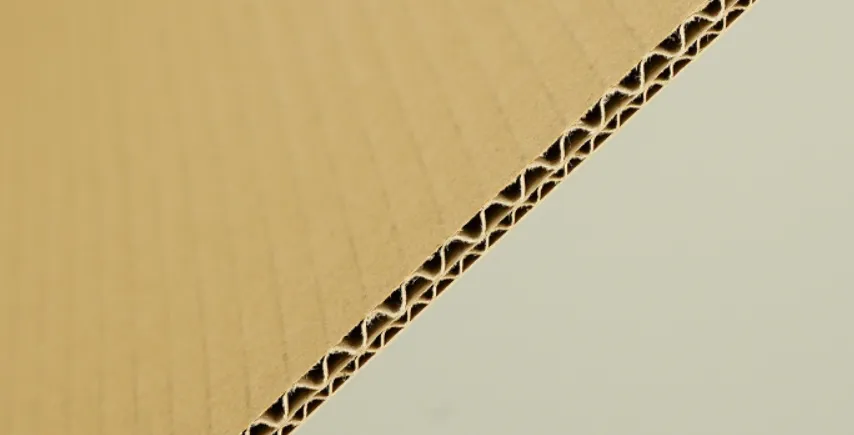

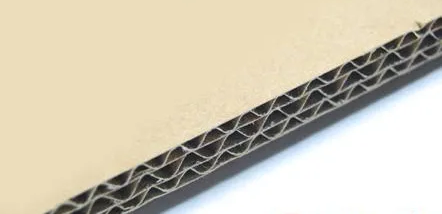

Pit paper is a smooth kraft paper and wavy paper (collectively referred to as paper core) mounted, also known as corrugated paper, which is more straight and has a stronger load-bearing capacity than ordinary paper. It is one of the important materials for paper packaging.

The most important use of pit paper is outer packaging, which has a variety of styles. Commonly used three layers (single pit), five layers (double pit), seven layers (three pits), etc

Three floors (single pit)

Fifth floor (double pit)

The seventh floor (three pits)

There are A, B, C, E, F, G in pit paper, but there are no D pits in H. The difference between E, F, and G pits is that the pit patterns are smaller and finer, and they have maintenance power and are not rough. Printing in various colors can be realized, but the effect is not as good as that of single copper paper.

The commonly used surface treatment processes after pit paper printing are: glue, UV, hot stamping, and embossing.