Learn about 20 beautiful printing and packaging processes (1-4)

The printing industry is fiercely competitive and the market is quite stalemate, and the transformation and upgrading of enterprises is imminent. With the intensification of the elimination and reshuffle, all walks of life are showing the "Matthew effect" of gathering to big brands. Big brands pay far more attention to product packaging than small brands, which not only puts forward higher requirements for the printing process, but also brings a once-in-a-lifetime opportunity for package printing companies to improve the added value of products.

Here, the most powerful printing process is specially selected for the overprinting enterprise.

Process name 1:

Offset printing silver ink + four colors, offset printing gold ink + four colors

Features: Under the local four-color graphics, due to the gold or silver ink base, it flashes with a wonderful and bright metallic luster.

Processing method: offset gold ink or silver ink + four colors, 240 lines, CTP thermal version.

Scope of application: posters, fashion album binding, corporate brochures, real estate advertising sheets, etc.

Note: The gold or silver version should be reduced with the change of the graphic color, and the picture effect is more vivid.

Substrate: P0901 super bright copper, P0903 super snow copper, 157g/m2, origin: China.

Material characteristics: paper fibers are evenly distributed, the thickness is consistent, the flexibility is small, and the printability is good.

Process name 2:

Screen printing silver ink, screen printing gold ink

Features: The ink color is thick, the ink layer is thick, and the visual impact is strong, but the picture is not delicate enough and the sense of hierarchy is not strong.

Processing method: screen printing bright silver ink, screen printing red gold ink, 100 lines of film, 250-300 mesh, oblique mesh.

Scope of application: cultural posters, product pendants, high-end cosmetics, hardcover book binding, packaging god boxes, etc.

Note: Screen printing gold and silver ink is best prepared in advance and fully reconciled and then printed on the machine, the effect is better.

Substrate: loose green paper, 110g/m2, super orchid, 150g/m2, origin: China.

Material characteristics: super orchid, the paper surface is elegant and soft, the paper texture is natural and simple, the texture is soft, warm, and the feel is unique.

Process name 3:

Black anodized aluminum

Features: Add a hot stamping process to a certain detail of the printed matter to achieve unexpected results.

Processing method: offset printing four colors, seal stamping, black anodized aluminum.

Scope of application: cultural publications, posters, book rings, product catalogs, greeting cards, etc.

Note: Choose the appropriate anodized aluminum color, and the alignment requirements for hot stamping are very accurate.

Substrate: Chuangworld, 120g/m2, origin China.

Material characteristics: Made of 100% waste paper, it belongs to recycled environmentally friendly paper, and has the characteristics of handmade paper, simple and nostalgic.

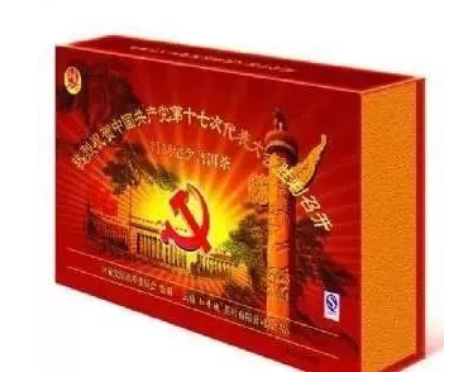

Process Name 4:

Offset printing four colors + stamping hot gold anodiz

e d

d

lFeatures: The colors are bright and strong, forming a huge contrast with the previous page, and a strong impact.

Processing method: offset printing four colors, 220 lines, seal stamping gold anodized aluminum.

Scope of application: cultural printed materials, book binding, festive packaging god boxes, holiday greeting cards, etc.

Note: When offset printing, try to make the ink cartridge as large as possible to get a stronger color.

Substrate: Piaorui, 120g/m2, origin: China.

Material characteristics: elegant, soft, the paper texture is natural and simple, the texture is soft, warm, and the feel is unique.uminum.

There are only four printing processes in this article. If you are interested in printing processes, or need to customize the packaging box, please click the link: https //www.risedongsheng.com

Scan the code on your mobile phone to learn more: