Introduction To The Printing Process Of China Xiamen Printing And Packaging Factory

The printing processing is the issue that many novices not understand well. With the development of printing technology, the printing processing has become more and more abundant. Generally, “post- printing” refers to the subsequent processing of printed matters, such as laminating, UV, hot stamping, embossing, debossing, die cutting, etc.

1.UV

UV refers to the Ultraviolet Rays,and the ink can be dried and cured by ultraviolet radiation. UV is usually a silk printing process, and now there is also offset printing UV.

Definition: a special process for curing the UV photoresist on the surface of the printed product in full or partially

Features: A variety of artistic special effects can be presented on the surface of the printed matter to make the printed matter more exquisite

Type: thick UV, frosted UV, colorful UV, glass beads, sprinkled colorful powder, etc.

Scope of application: book mounting, envelopes, covers, desk calendars, high-end packaging, handbags, etc.

Note: If you use UV on the lamination, you need to use a special UV lamination, otherwise the UV is easy to fall off, bubbles, glue-opened. The effect of UV will be better together with some special processes such as embossing and hot stamping.

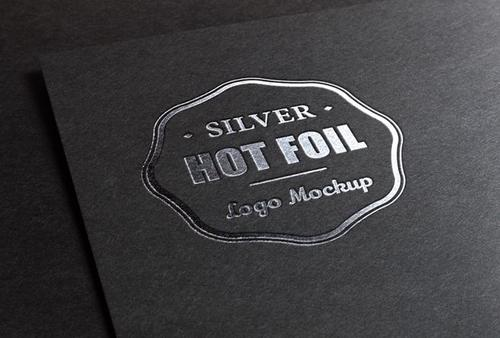

2.Gold Stamping/ Silver stamping

It calls hot stamping, widely known as gold stamping and silver stamping. It is a method of hot stamping the metal foil on the printed matter through a certain pressure and temperature, and there is also a cold gilding printing process.

Gold stamping

Silver stamping

Features of hot stamping: metallic luster, magnificent, and obvious difference from printing process

Scope of application: suitable for prominent text or logo, mostly used for samples, greeting cards, invitations, wall calendars, desk calendars, etc.

Note: It can be more pronounced with the embossing or debossing process; besides gold and silver, the colors that can be used include laser light, pantone color, etc.

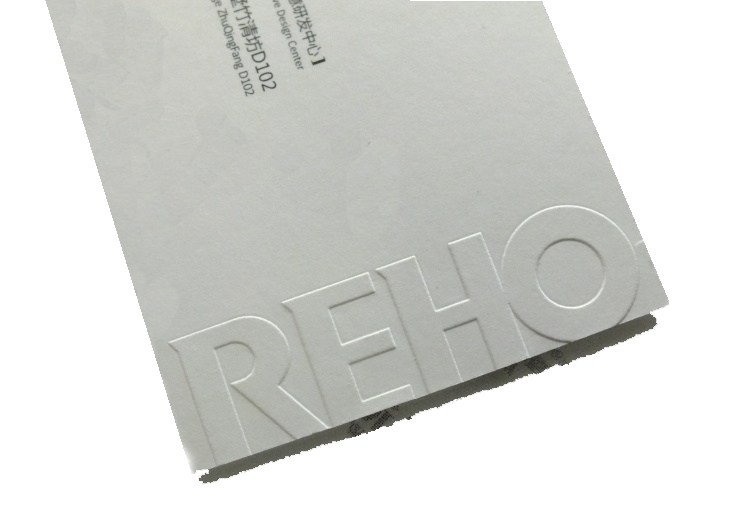

3.Embossing and debossing

Definition: Use convex template (Yang template) or concave template (Yin template) to impress the surface of the printed matter into a relief-like pattern with three-dimensional or concave sense (the printed matter is partially convex or concave to make it three-dimensional). , Causing a visual impact).

embossing

Features: can increase the three-dimensional sense

Scope of application: suitable for paper of more than 200gsm, high-weight special paper with obvious sense of mechanism

Note: The effect is better when combined with hot stamping, local UV and other processes.

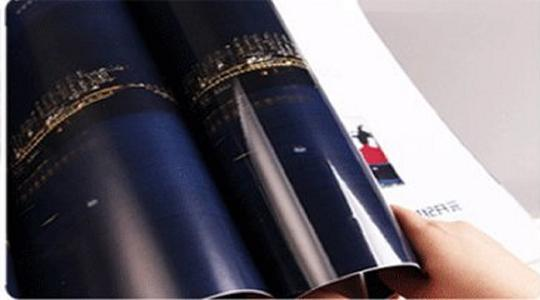

4.Lamination

Add a layer of transparent plastic film on the printed paper, such as glossy lamination, matte lamination, soft touch lamination, etc.

Glossy lamination

Matte lamination

Definition: The processing technology of covering a plastic film on the surface of a printed matter and using an adhesive to bond them together after heating and pressing to form a printed matter of paper and plastic.

Features: The surface of the glossy lamination product is bright and expressive, and it is mostly used for product printing; the surface of the product with matte lamination is non-reflective and elegant, and it is mostly used for image printing.

Scope of application: For papers above 200gsm, if there are creases on the solid color parts, the laminating process is needed.

Note: Papers with a thickness of 128 grams or less are easily rolled after being coated on one side with different surface tensions on both sides; the color saturation of the printed matter will slightly decrease after being coated with a matte lamination.

5. Die cutting

The die-cutting process is a forming process in which a special dieline is made according to the design requirements of the printed matter, and then the printed matter or other substrates are rolled into the required shape or cut under the action of pressure.

Definition: the process of using steel knives and steel wires to form a template and processing printed matter into the required shape under pressure

Features: Abnormal shapes can be produced and expressiveness enhanced

Scope of application: It is suitable for products that use more than 157gsm of paper as raw materials, such as stickers, trademarks, gift boxes, other printed artworks, etc.

Xiamen Rise Dongsheng Import & Export Co., Ltd., a professional manufacturer of packaging enterprise, with more than 15 years experience,we can do OEM or ODM service, Our workshops mainly produce Paper box,packaging boxes,gift box,Jewelry box,cosmetic box,Cake box,Chocolate box,Wine box,Candle box,Corrugated Box,Paper Bag,Shopping bag.More information about our company and inproductions ,please mail to sales1@huakangortho.com or enter our web Chris@risedongsheng.com